James Adams, ~1846 - 1926

by Brian Stevenson

last updated November, 2015

Microscope slides are occasionally seen that were made by James Adams, of Dunfermline, Scotland (Figure 1). Many are thin sections of coal and substances related to coal mining and processing. Adams' family owned a major mine and factory complex at the Hill of Beath, where they produced both coal and a wide variety of clay and ceramic products. James evidently earned a good income, with ample leisure time. He was a member of the Royal Microscopical Society, the Edinburgh Field Naturalists' and Microscopical Society, the Mining Institute of Scotland, and, probably, the Society of Antiquaries of Scotland.

Figure 1.

Examples of microscope slides that were made by James Adams. He identified his work with either large descriptive labels or small circles. His handwriting helps identify slides from which his name labels are now absent. All of the above came from the same Scottish collection.

Figure 2.

An 1877 advertisement for the Hill of Beath Coal Company, from Worrall’s Directory.

James Adams was born ca. 1846 in Hamilton, Lanarkshire, Scotland, the second son of Ord and Susan Taylor Adams. The 1851 census lists the father’s profession as “coal grieve”, (overseer or manager). The family then consisted of 3 sons and 5 daughters, and employed a domestic servant.

In about 1860, through as-yet unknown circumstances, father Ord Adams acquired and developed a coal mine at Hill of Beath, Fifeshire. Directories of the period list Ord Adams as being a member of the local gentry. In 1892, the Dunfermline Journal described the works, “If there are some Rip Van Winkles in the Western District of Fifeshire who have been asleep during the last half century and are anxious to have an idea of the great progress which has been made in mining since 1840, they could not do better than make a tour round the Fife Coal Company’s works at Hill of Beath. The late Mr. Ord Adams began operating on a very extensive scale at Hill of Beath upwards of 30 years ago (i.e. ca. 1860). The great engine pit he sunk on the eastern slope of the Hill of Beath was a big venture compared with many of the small pits and clay-mines opened up in many of the districts in Fife. In 1887 Mr. David Adams, fully alive to the tendencies of the age, inaugurated the work of extending the colliery on a huge scale by contracting for sinking on the borders of the Hill of Beath and Dalbeath grounds, and the pit put down is undoubtedly the largest pit in Scotland. In 1889 the work passed into the hands of the Fife Coal Company”.

Archibald Geikie described that the “Fourteen-foot” coal level of the Hill of Beath contained “fire-clay 15 inches thick, (which) forms the roof of that coal”. The Adams’ made good use of that clay.

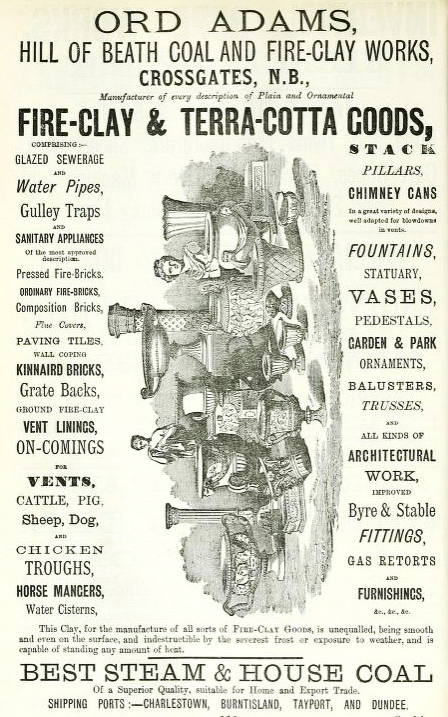

Worrall’s Directory of 1877 described the town of Crossgates as “a village partly in the parish of Dunfermline and partly in that of Dalgetty, about a quarter of a mile from the station on the North British Railway. The manufacturing of fire clay and terra cotta goods is extensively carried on here by Ord Adams, Esq., and affords employment to a number of the inhabitants of this district”.

The brick and ceramic factory evidently passed into James’ hands, while David ran the coal mine. The 1871 census listed James, David, and 4 sisters living with Ord (Susan passed away a few years earlier). James’ occupation was recorded as “fire clay works hires 4 men”, while father Ord was a “coal proprietor”, and David was a “coal manager”. The description from 1877, noted above, suggests that the clay works expanded between 1871 and 1877, but probably also included the miners who dug the clay and other workers who were involved in transport.

During the 1870s, James married Rankine McGeachin. The couple did not have any children. The 1881 census listed them as living on Douglas Street, Dunfermline, Fifeshire, and employing one domestic servant. James’ occupation was “fire clay goods manufacturer”.

At the time of the 1891 census, James, Rankine, and her younger sister were taking water treatments at the Glenburn Hydropathy facility in Rothesay, Bute.

James had retired by the time of the next census, in 1901, although only 55 years old. He lived at 10 Comely Park, Ambleside, Dunfermline, with Rankine and her sister, along with a cook and domestic.

There are very few known records about Adams’ interest in microscopy. He was elected to be a Fellow of the Royal Microscopical Society on May 17, 1893. There is no evidence that he attended any meetings in London. He remained a member through at least 1923.

Of other scientific interests, in 1898 he donated to the Society of Antiquaries of Scotland, a “polished axe of greenish quartz (broken), found at Pitreavie near Dunfermline. This fine axe, which is beautifully formed and highly polished, is made of a material which has been called a greenish quartz, but has a very close resemblance to jadeite. It measures 4 3/4 inches in length, and must originally have been about 7 1/2 inches in length, part of the butt end having been broken off and lost. The width across the cutting face is 4 3/4 inches, and the greatest thickness 5/8 of an inch”.

An interest in photography, radiation, and electricity is evident from a brief article he wrote in 1901, “Mr. James Adams, Comely Park, Dunfermline, sends the following notes on the effects of the electric discharge from a coil on a sensitized photographic plate. The current from the 10-inch induction coil at the Dunfermline Cottage Hospital was accidentally turned on for a few seconds before the wires were connected to the tube. The wires were resting on the table within an inch or two of the plate, and were supported from a high stand resting on the floor; the plate was on the baseboard of the tube-holder on the table. The lady's hands were on the plate at the time, and she felt a slight shock, but there was no sparking or disruptive discharge. The cathode was at the lady's right hand. After the plate was removed from the envelope the latter was carefully examined with reflected and transmitted light and a good lens, but no punctures could be observed, neither was the paper nor the film on the plate burned or marked in the least”.

In 1904, he donated to the Royal Scottish Museum, “seven specimens of Queen Bees, three ‘royal’ cells, and a portion of comb; Piece of metal gas pipe bored by Sirex gigas, also the insect which caused the damage; a collection of Carboniferous Micro-Fossils, chiefly from Lanarkshire”.

James Adams died August 14, 1926, at Cowdenbeath, Fifeshire.

Figure 3.

Two clay bricks from the Adams’ Hill of Beath factory. The left bears Ord Adams’ name, while the right one lists only the business name, and may, therefore, date from the time that James owned the business. Adapted for nonprofit, educational purposes from http://www.scottishbrickhistory.co.uk/ord-adamshill-of-beath-crossgates/, and http://www.scottishbrickhistory.co.uk/hill-of-beath-3/

Figure 4.

Section of Agate, by James Adams. Photographed using a C-mounted SLR digital camera on a Leitz Ortholux II with a 3.4x objective lens and crossed polarizing filters.

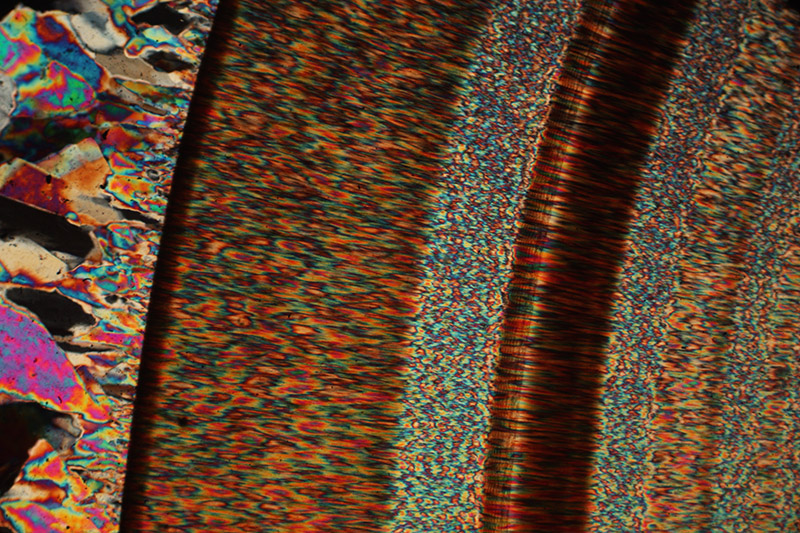

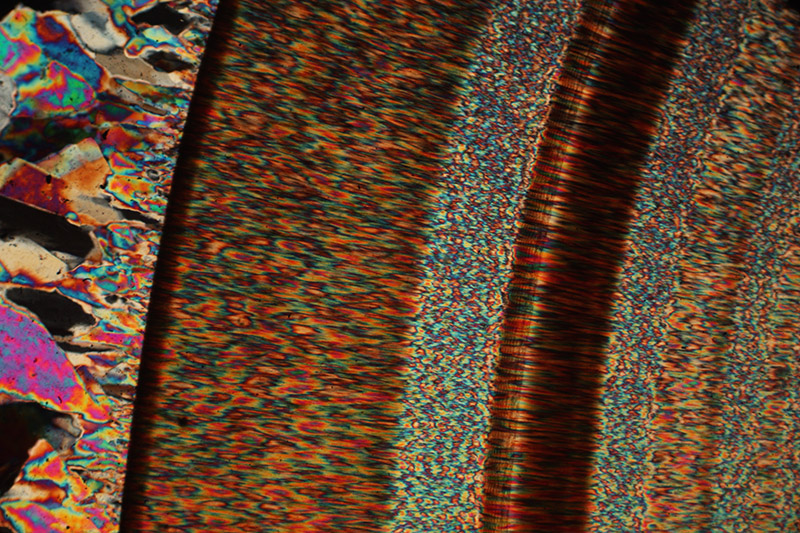

Figure 5.

“Incrustation, hot water feed pipe, Hill of Beath, Engine Pit steam boilers, 1883”, by James Adams. Photographed using a C-mounted SLR digital camera on a Leitz Ortholux II with a 3.4x objective lens and crossed polarizing filters.

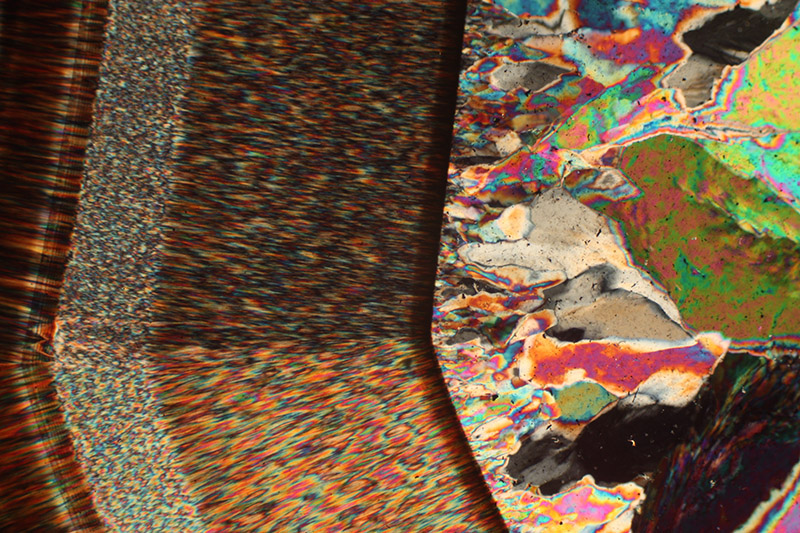

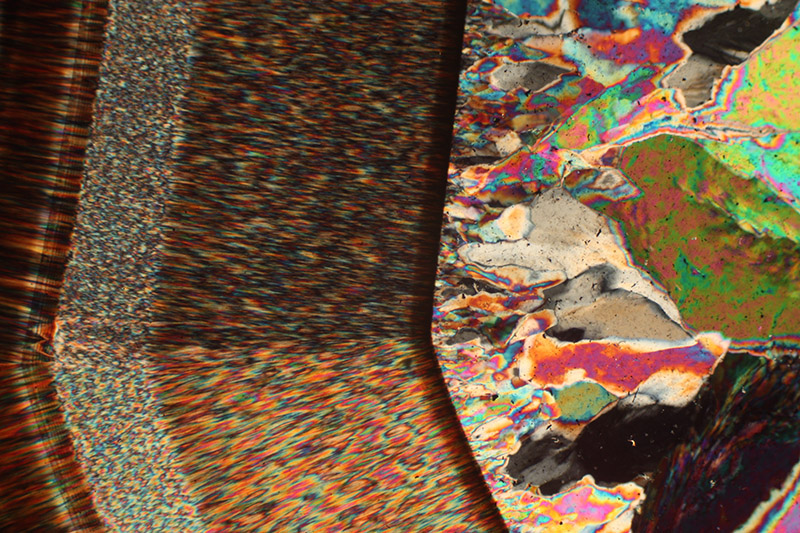

Figure 6.

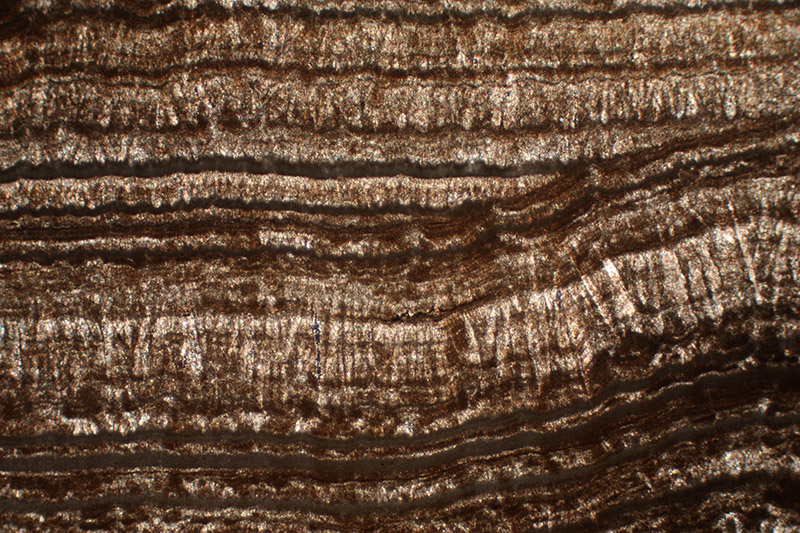

“Coal, Fourteen Feet, Engine Pit, Hill of Beath, Fife, vertical section”, showing a refracting inclusion, by James Adams. Photographed using a C-mounted SLR digital camera on a Leitz Ortholux II with a 10x objective lens and crossed polarizing filters.

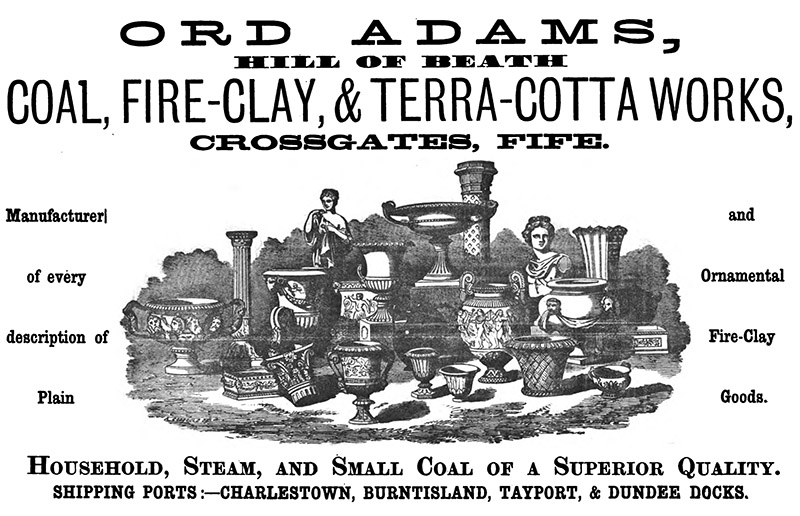

Figure 7.

An 1878 advertisement, describing many of the ceramic items produced by the Adams’ Hill of Beath Coal and Fire-Clay Works. From Slater’s Directory.

Resources

Archives of the Roentgen Ray (1901) Effects of electric discharge on a photographic plate, Vol. 5, page 80

Dunfermline Journal (1892) The rise & progress of the village of Hill of Beath, November 19, accessed through http://www.scottishmining.co.uk/268.html

Find-a-Grave (accessed November, 2015) Description of the grave of James Adams, Mossgreen Cemetery, Cowdenbeath, Fifeshire, http://www.findagrave.com/cgi-bin/fg.cgi?page=gr&GRid=114810504&ref=acom

Geikie, Archibald (1900) The Geology of Central and Western Fife and Kinross, Her Majesty’s Stationery Office, Glasgow, page 205

Journal of the Royal Microscopical Society (1893) Election of James Adams, May 17, page 426

Journal of the Royal Microscopical Society (1923) “List of members: 1893 Adams, James. Comely-park, Dunfermline, N.B.”

Proceedings of the Society of Antiquaries of Scotland (1898) Description of donations from James Adams, Vol. 32, pages 129-130

Royal Scottish Museum, Report of the Director (1904) List of donations from James Adams, page 9

Scotland census and death records, accessed through ancestry.co.uk

Scottish Brick History (accessed November, 2015), images of bricks from Hill of Beath Works, http://www.scottishbrickhistory.co.uk/ord-adamshill-of-beath-crossgates/, and http://www.scottishbrickhistory.co.uk/hill-of-beath-3/

Slater’s Directory (1878) Advertisement from Hill of Beath Coal, Fire-Clay, and Terra-Cotta Works

Transactions of the Edinburgh Field Naturalists' and Microscopical Society (1903) “List of members: Adams, James. Comely-park, Dunfermline”, Vol. 5

Transactions of the Mining Institute of Scotland (1880) Election of James Adams to membership, November 11, Vol. 2, page 137

Worrall's Directory of the North-Eastern Counties of Scotland (1877) “Coal Proprietors: Adams Ord. Hill of Beath Coal, Fire Clay, and Terra Cotta Works, Crossgates. Shipping ports, Charlestown, Burntisland, Tayport, and Dundee”, description of Crossgates, and advertisement from Hill of Beath Coal and Fire-Clay Works, page 112