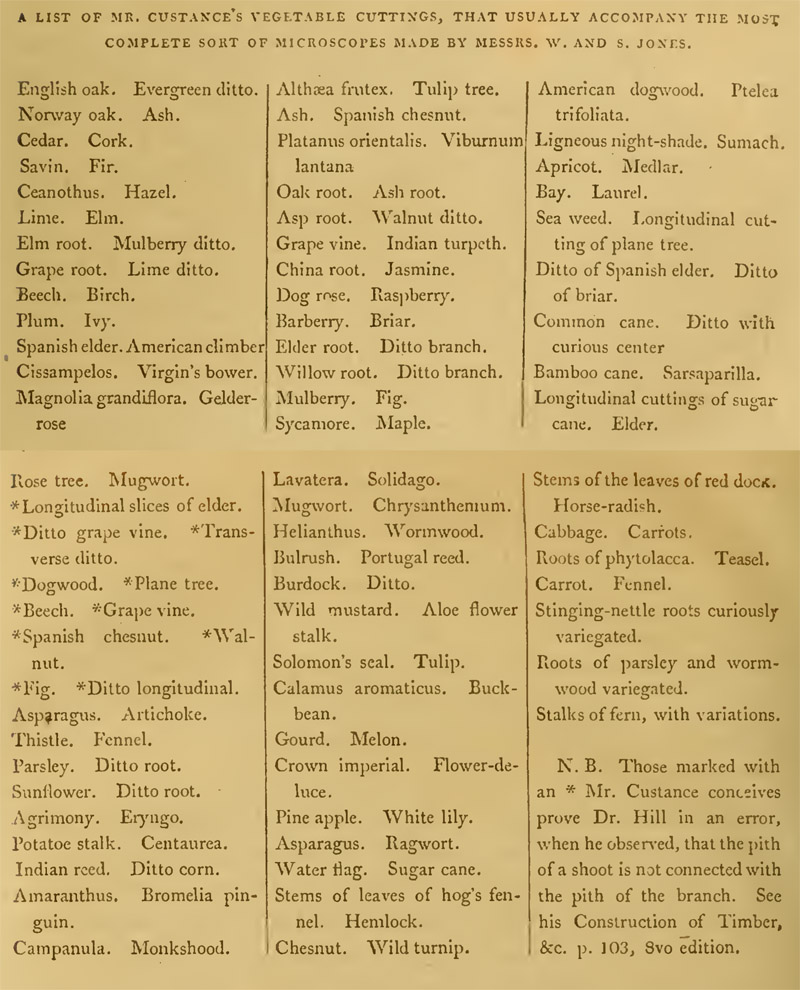

Figure 1. A 1798 list of Robert Custance’s specimens, from George Adams’ ‘Essays on the Microscope’, second edition. David Brewster reproduced this list in his 1832 ‘Edinburgh Encyclopedia’, 33 years after Custance’s death.

Robert Custance, ca. 1740 – 1799

by Brian Stevenson

last updated February, 2018

We usually think that the making of microscope slides did not become a viable profession until the second quarter of the 1800s, when that era’s scientific revolution brought high demand for microscopes, slides and other such materials. However, Robert Custance earned a living as a slide maker several decades before the “Golden Age of the Microscope”. This “common carpenter from Ipswich” produced such perfectly-sliced sections of woods that George Adams credited Custance as a major reason for the resurgence in microscope development in the late 1700s. His reputation persisted for many decades after his death.

All of Custance’s preparations were specimens of woods and other plant materials. These were mounted between mica (“talc”), in sliders that were made of either wood or ivory. His sliders had 4 specimens each, and the sliders were described as being larger than the common kind. The second, 1798 edition of George Adams’ Essays on the Microscope included a detailed “list of Mr. Custance’s vegetable cuttings” (Figure 1). The list also noted that Custance’s mounts “usually accompany the most complete sort of microscopes made by Messrs. W. and S. Jones” (who were also the book’s publishers). Jones’ catalog stated that they supplied Custance’s sliders in sets of six to four dozen, in addition to inclusion with their best microscope sets. On rare occasions, sliders matching the descriptions of Robert Custance’s work appear at auction (Figures 2-4).

Figure 1.

A 1798 list of Robert Custance’s specimens, from George Adams’ ‘Essays on the Microscope’, second edition. David Brewster reproduced this list in his 1832 ‘Edinburgh Encyclopedia’, 33 years after Custance’s death.

Figure 2.

A set of six sliders that match

descriptions of Custance’s preparations: thin sections of woods and other plant

materials that match his 1798 list, mounted in large ivory sliders, with four specimens per

slider. A standard 1x3 inch slide is shown in the lower right image as a size

comparison. At the bottom is an excerpt from W. & S. Jones’ 1798 price

list, indicating that such slides were available in sets of 6 to 48. Images

courtesy of Richard Courtiour.

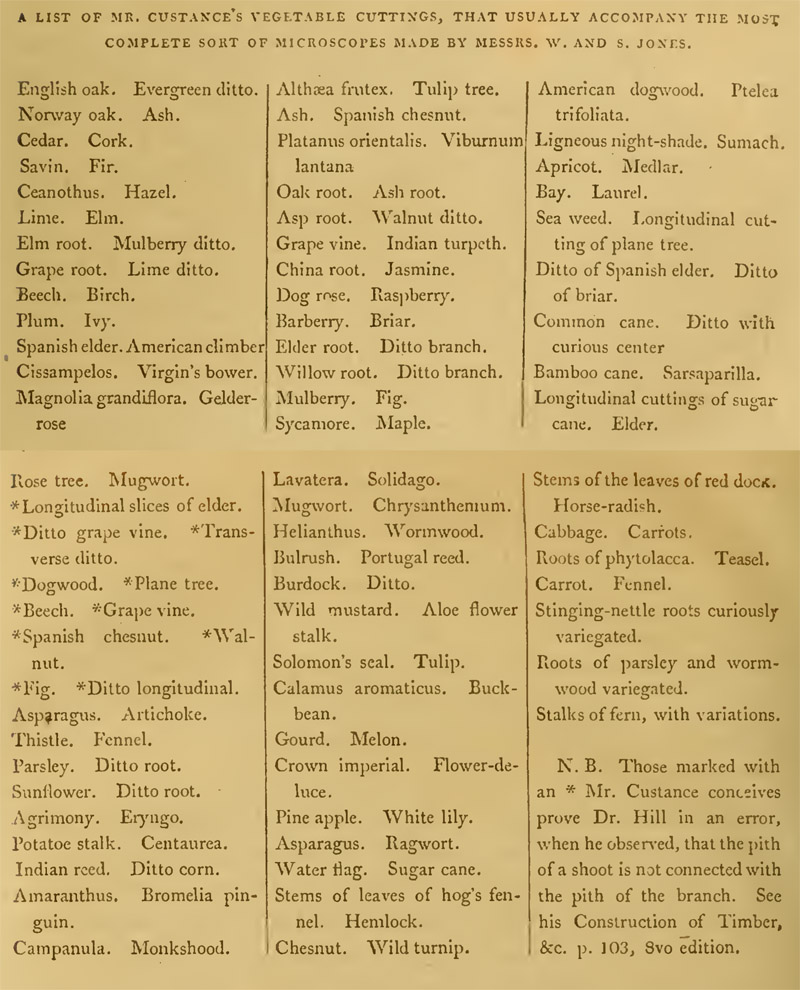

Figure 3.

Three wooden sliders that match descriptions of Custance’s preparations: "of box wood, each containing four cuttings or slices of some root or stem". The slides are each approximately 10 cm / 4 inches long.

Figure 4.

Two wooden sliders, each with five botanical specimens, with handwritten descriptions for each specimen. They resemble the ivory sliders shown in Figure 2, and include specimens known to have been mounted by Custance. The slides are each approximately 10 cm / 4 inches long.

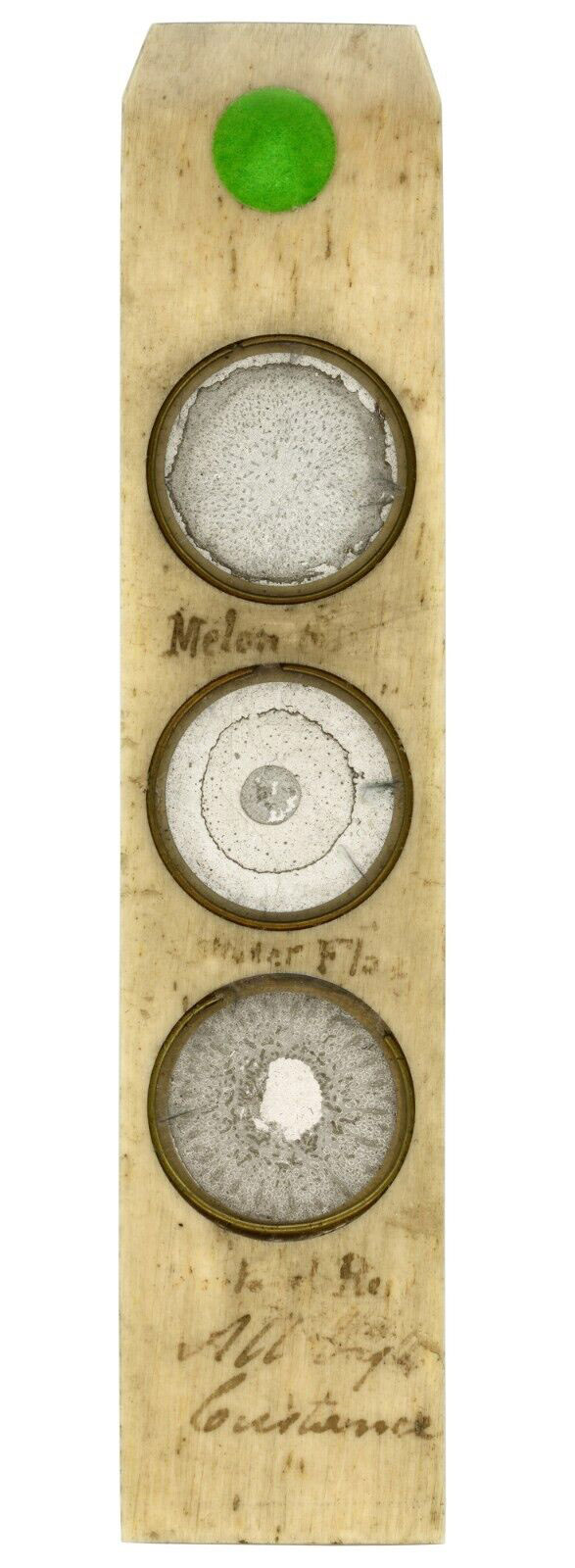

Figure 5.

An ivory slider, with three botanical specimens, with handwritten descriptions and the name "Custance". The slider is approximately 4 inches / 10 cm inches in length. Adapted for nonprofit, educational purposes from an internet auction site.

Both editions of Adam’s Essays on the Microscope (1787 and 1798) described the important role Custance played in revitalizing microscope development in England:

Following the initial excitement of the instrument’s invention in the late 1600s, enthusiasm waned. Adams wrote, “After this period, the mind, either satisfied with the discoveries already made … or tired by it's own exertions, sought for repose in other pursuits; so that for several years this instrument was again, in some measure, laid aside”.

This changed dramatically after John Hill, a physician and botanist, wrote The Construction of Timber from its Early Growth, Explained by the Microscope, and provided an important, practical use for the microscope. Adams continued, “In 1770, Dr. Hill published a treatise, in which he endeavours to explain the construction of timber by the microscope, and shew the number, the nature, and office of its several parts, their various arrangements and proportions in the different kinds; and point out a way of judging, from the structure of trees, the uses they will best serve in the affairs of life. So important a subject soon revived the ardor for microscopic pursuits, which seems to have been increasing ever since”.

Adams then gave credit of the invention of the microtome to his father, George Adams Sr., although that was probably self-serving, “About the same time, my father contrived an instrument for cutting the transverse sections of wood, in order that the texture thereof might be rendered more visible in the microscope, and consequently be better understood; this instrument was afterwards improved by Mr. Cumming (clockmaker Alexander Cumming). Another instrument for the same purpose, more certain in it's effects, and more easily managed, is represented in (the book). Dr. Hill and Mr. Custance now endeavoured to bring back the microscope nearer to the old standard, to increase the field by the multiplication of the eye glasses, and to augment the light on the object, by condensing lenses; and in this they happily succeeded: Mr. Custance was unrivalled in his dexterity in preparing, and accuracy in cutting thin transverse sections of wood”. Adams illustrated several sections of woods as viewed under the microscope (Figure 7), stating that, “the sections were cut by Mr. Custance, who first brought this art to perfection, and remains unrivalled as yet in these performances”.

Some details of Custance’s preparations were provided by John Towers in 1830, “But the most beautiful exemplification of the structure of woody stems, is to be found in those natural specimens which are sold by mathematical instrument makers. There is, or was, a set of these prepared specimens, known by the name of Custance’s vegetable cuttings: it consists of twelve sliders of box wood, each containing four cuttings or slices of some root or stem, between two fine and transparent pieces of talc. These slices are so prepared as to exhibit the natural vascular structure; the woody fibre, that encloses the vessels, lying in concentric layers, and the medullary, or divergent rays, crossing them in a horizontal direction”.

Thomas Gill, writing in 1829 in his Gill’s Technological Repository, “The specimens of wood cuttings, … were made by the late celebrated Mr. Custance, and the Editor has many similar ones in his own collection of transparent microscopic objects. They are fully entitled to the encomiums passed upon them … and it is much to be regretted that no one has ever since been able to equal Mr. Custance's cuttings. He seems to have possessed methods, peculiar to himself, in the formation of his machine; and possibly, also, in the manner of preparing his woods for cutting”.

As late as 1855, John Quekett raved about Custance’s work, “In 1770, Dr. Hill published a treatise, entitled The Construction of Timber explained by the Microscope, in which not only were the nature and office of its several parts pointed out, but also the way of judging from the structure, the uses to which the different kinds could be best applied. This work created a great sensation at the time, and revived the ardour for microscopic pursuits. Adams, at this period, invented a machine for cutting transverse sections of wood so thin, that they might readily be examined by the microscope. This instrument was subsequently improved on by Mr. Cumming, and with it very beautiful sections were made by Mr. Custance, some of which stand unrivalled even at the present day”. Although the passage was largely plagiarized from Adams, Quekett was probably sincere in his compliment of Custance’s sections being “unrivalled even at the present day”. He was, however, incorrect in assuming that Custance used Cumming’s section-cutter. Custance’s instrument was very different from that of Cumming. A description of the Custance microtome is included near the end of this essay.

Insights on Custance’s life come from this obituary, “At his apartments in Upper Mary-la-Bonne street, Mr. Custance, a very eccentric, yet very worthy character. He was originally a carpenter, but for many years past followed an employment more suitable to his wishes, leaving him more time to prosecute his studies. His indefatigable application to observations, both with the telescope and microscope, rendered him an acute observer of the works of creation, from its minutest object to the more sublime appearance of the heavenly bodies, in both which departments of science the many important discoveries he made are sufficient to rescue his name from oblivion. He excelled, in a high degree, in the art of preparing vegetable and other bodies, for the purposes of microscopical inspection, of which he has given the world many curious and unequalled specimens, and has left a valuable and excellent philosophical apparatus behind him, which his economical and abstemious way of living for many years had enabled him to purchase. His apartment formed a complete museum; and what with books, instruments, pictures, natural curiosities, together with a large finger-organ, he had scarcely room left for his bed and a few chairs. Among many other eccentricities, he never suffered any person to do any thing for him; he kept no servant, nor was ever married; he cooked and did every thing for himself, and was never in any house of public entertainment for 35 years. He was temperate, pious, and of the strictest integrity; while his communicative disposition and attentive assiduities endeared him as much to those who had the pleasure of knowing him, as his many peculiarities of living and dress attracted the notice of those who were but superficially acquainted with his character”. Custance was buried January 16, 1799, at St. Marylebone.

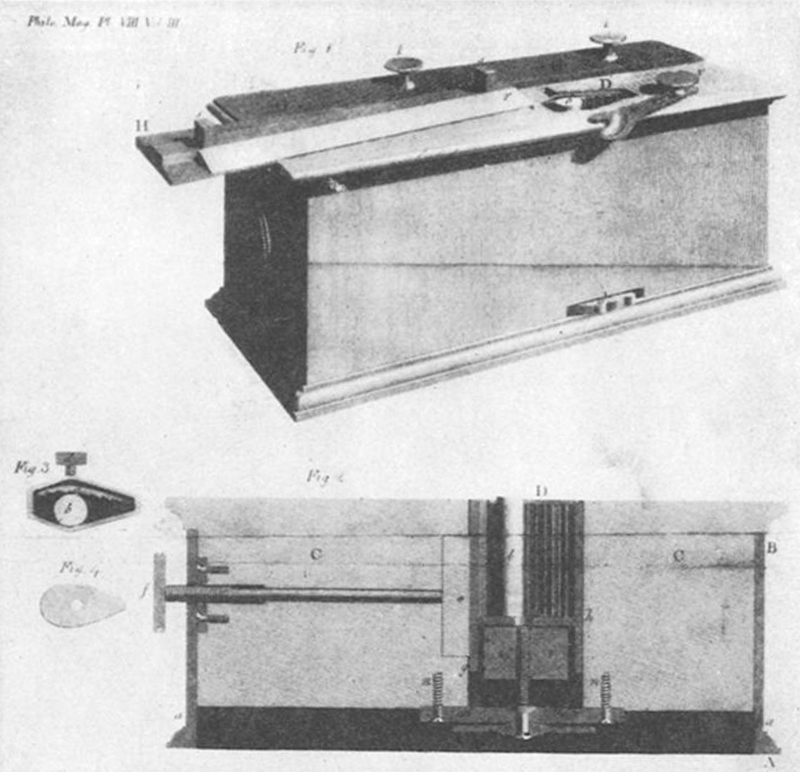

Figure 6.

Diagrams of Robert Custance’s microtome, showing a view

(top) and cross section (bottom). Essentially, a twig or other thin piece of

plant material was held firmly in a vertical position, while a horizontal knife

was pushed across at an angle, thereby using both the sharp knife-edge and

friction to slice a thin section off the plant. A fine adjustment raised the

plant piece up a precise distance between cuts. Adapted from Smith’s ‘The

development of botanical technique’, who adapted it from Thornton’s 1799 paper

which appeared in ‘The Philosophical Magazine’, 1799.

Robert Thornton (ca. 1768–1837) acquired two of Custance’s microtomes, thereby preserving a record of both their appearance (Figure 6) and their function. His Account of the new machine invented by the late Mr. Custance, for making vegetable cuttings for the microscope is reprinted in full:

“The first idea of making vegetable cuttings to be examined by the microscope, originated from the famous Dr. Hooke above a century ago, as may be seen in his Micrographia.

‘Charcoal, or a vegetable burnt black’, says this eminent philosopher, ‘affords an object no less pleasant than instructive; for if you take a small round piece of charcoal, and break it short with your fingers, you may perceive it to break with a very smooth and sleek surface, almost like the surface of black sealing wax, this surface, if it be looked on with an ordinary microscope, does manifest abundance of those pores which are also visible to the eye in many kinds of wood, ranged round the pith, both in a kind of circular order, and a radiant one. Of these there are a multitude in the substance of the coal, every where almost perforating and drilling it from end to end; by means of which, be the coal ever so long, you may easily blow through it; and this you may presently find, by wetting one end of it with spittle, and blowing at the other.

But this is not all: for, besides those many great and conspicuous irregular spots or pores, if a better microscope be made use of, there will appear an infinite company of exceedingly small and very regular pores, so thick and so orderly set, and so close to one another, that they leave very little room or space between them to be filled with a solid body; for the apparent interstitia, or separating sides of these pores, seem so thin in some places, that the texture of a honeycomb cannot be more porous: though this be not every where so, the intercurrent partitions in some places being very much thicker in proportion to the holes.

Most of these small pores seemed to be pretty round, and were ranged in rows that radiated from the pith to the bark; they all of them seemed to be continued open pores, running the whole length of the stick; and that they were all perforated, I tried by breaking off a very thin sliver of the coal cross-ways, and then with my microscope diligently surveying them against the light, for by that means I was able to see quite through them.

These pores were so exceedingly small and thick, that in a line of them, 1/18 part of an inch long, I found, by numbering them, no less than 150 small pores; and therefore, in a line of them an inch long, must be no less than 2700 pores; and in a circular area of an inch diameter, must be about 5,735,350 of the like pores; so that a stick of an inch diameter may contain no less than seven hundred and twenty-five thousand, besides 5 millions of pores, which would, I doubt not, seem even incredible, were not every one left to believe his own eyes. Nay, having since examined cocus, black and green ebony, lignum vitæ, &c. I found that all these woods have their pores abundantly smaller than those of soft light wood; in so much that those of guajacum seemed not above an eighth part of the bigness of the pores of beech, but then the interstitia were thicker; so prodigiously curious are the contrivances, pipes, or sluces by which the succus nutritius, or juice of a vegetable, is conveyed from place to place’.

He afterwards says, ‘I took a good clear piece of cork, and, with a pen-knife sharpened as keen as a razor, I cut a piece of it off, and thereby left the surface of it exceeding smooth; then examining it very diligently with a microscope, methought I could perceive it to appear a little porous; but I could not so plainly distinguish them as to be sure that they were pores, much less what figure they were of: but judging from the lightness and yielding quality of the cork, that certainly the texture could not be so curious, but that possibly, if I could use some further diligence, I might find it to be discernible with a microscope, I, with the same sharp pen-knife, cut off from the former smooth surface an exceeding thin piece of it; and placing it on a black object plate, because it was itself a white body, and casting the light on it with a deep plano-convex glass, I could exceeding plainly perceive it to be all perforated and porous, much like a honey-comb, but that the pores of it were not regular; yet it was not unlike a honey-comb in these particulars.’

This is the first rude hint respecting the mode of cutting of Vegetables, since which time cutting machines have been contrived by several ingenious mechanics, that might better perform this delicate operation. In 1770 Dr. Hill published a treatise, in which he explained the construction of timber by means of vegetable cuttings examined by the microscope; and he in that work gives an account of a cutting engine, in which a spiral knife is employed; the invention, he says, of Mr. Cummings. The late Mr. Adams, optician in Fleetstreet, appears to have contrived a machine for cutting thin sections of wood, in order that the texture thereof might be more visible to the microscope; and in his Essays on the Microscope, he says, that this his invention was afterwards improved by Mr. Cummings. Notwithstanding the application of Dr. Hill, and of others who attempted to bring this art to perfection, Custance, a common carpenter from Ipswich, surpassed every other, and, as Mr. Adams justly observed, continued unrivalled in his dexterity of preparing thin sections of wood, having brought this art to the highest perfection. He cautiously kept his method a secret from every one, and various conjectures were made in what way he accomplished his unrivalled cuttings. When he was alive, I offered him fifty pounds for the discovery, to disclose it to the world for the promotion of science, and in order the better to accomplish my views in my New Illustration of Linnaeus, where the organisation of vegetables is a particular object of consideration. When pressed, he offered me the discovery for an hundred guineas, which thinking exorbitant, I gave up all thoughts of it; but, soon after dying, he left in his will, that every thing he possessed should be put up to public auction; and, among other things, his invention of the cutting engine was particularly noticed in the catalogue. They were not, however, exposed to examination, but I did not fail being at the sale to embrace this opportunity of bidding for the two engines, fearful that a monopoly might be made of the art of preparing vegetable cuttings, as had been successfully done by distance. Although the opposition was strong, I was the successful bidder, and became possessed of both engines, which are constructed nearly upon the same principle; and I am happy to embrace the present opportunity of communicating to the public so valuable an acquisition to philosophy and science.

Custance's best Cutting Engine described.

(Figure 6, top) represents a view, and (Figure 6, bottom) a section, of the cutting machine. It has the appearance of an oblong box, and the sides from the bottom (A) up, to (B) are made of brass. A piece of hard mahogany, (CC), is fitted into the brass box, and fills the whole cavity down to (aa), leaving a void space at the bottom, of sufficient size to admit the parts of the machine which work there, and which are described below. From the top to the bottom of the wood there is a perforation, of which the outline of (Figure 6, upper inset) may be considered as representing a horizontal section, which receives easily a brass socket in which the wood (b) to be cut is secured in its place by means of a brass holdfast (c), grooved like a float file, and pressed against the wood by the screw (d). This socket, with the holdfast, (which viewed in front has a fluted appearance) and the piece of wood is represented in its place (D), where it is secured from shaking by means of the piece (e), pressed against it by the screws but not so tight as to prevent its being raised when required by the micrometer screw to be yet described. The socket, which fills the perforation from the surface (D) down to (g), has a horizontal division at (b), which serves as a bottom for the holdfast to rest on; the cavity of the socket below (b) receives a piece of metal (ii), of which (Figure 6, lower inset), is an horizontal section; through this piece, which moves easily up or down in the socket, is a female screw, in which the micrometer screw turns, which may be seen passing through (ii) in (Figure 6, lower). The micrometer screw, the neck of which works in a plate (mm), made fast to the bottom of the piece of mahogany before described by means of the screws (nn), is prevented from rising or fallings when turned round, by a conical shoulder fitted into the upper side of the plate (mm), as may be seen in the figure, and by the micrometer index wheel (oo) made fast to that end of the screw which projects through the lower surface of (mm). Therefore, when the index is turned, the screw working in (i) raises or lowers (i); the latter by its form being prevented from turning with the motion of the screw. The piece (i), being thus raised as much as the intended thickness of the slip to be cut, presses as it rises against the divisions, and by that means makes the brass socket, in which the wood is made fast as before described, to rise exactly the same quantity - care being taken to regulate the pressure communicated by the side screw in such a manner as just to allow free action to the micrometer screw, and yet to prevent any lateral deviation in the ascent of the socket. A portion of the index wheel comes through the front of the machine (o); and all that is necessary to raise the wood, the parts being previously adjusted in the manner described, is to lay hold of the knob that presents itself at the opening, and move it to the left, a half, a whole, or two divisions, according to the thickness the slip is wished to be cut. These divisions are marked on the circumference of the index, and you note the quantity that passes a stationary point marked over the centre of the opening.

The cutting apparatus is constructed in the following manner: On the further edge of the upper surface of the box, a flat rule, (GG), made of steel, is fastened down by the screws (kk); it is more than an eighth of an inch in thickness, and the front edge of it is ground perfectly straight, and stands at a right angle to the surface on which it rests. Another flat rule, one end of which, (H), may be seen projecting past the end of (G) towards the left, serves as a bed for the cutting knife (rr), which is made fast to the rule by the screws (ss). The upper and under surface of this rule are ground parallel to each other, and its back edge is ground straight to sit against the front edge of the rule (GG). The rule (H), which is moveable with the knife (rr), is tapered from the end, so as to be somewhat narrower at the end next to the cavity (D), than the diameter of the pieces of wood that can be contained betwixt the holdfast and the other side of the socket. From this the wonderful simplicity and accuracy of the process, as performed by this apparatus, must be obvious; for the socket, or in other words, the piece of wood from which the slip is to be cut, being raised to the desired height by turning the micrometer, all that is necessary is to slide the rule (H), with an even hand and pressure, along between the rule (GG) and the wood to be cut; the taper form of the knife, or rather of its bed, causing it to shave off, as the broad end comes nearer to the socket, a slip from the surface exposed to its action. It should be here remarked, that a portion of the bed (the rule H) is cut away from under the knife, from (r) to (r), to allow the knife to pass freely over the wood as it performs its office. To keep the wood perfectly fast in its place while the slip is cutting off, beside the holdfast in the socket already described, there is the following contrivance: A brass spur (u), a little thinner than the rule (H), having a circular notch at its widest end, which may be moved or made fast at pleasure by means of the screw (v), is brought up tight against the wood to be cut (the wood being embraced by the circular notch), and then screwed fast; the opening at the narrow end of the spur, through which the screw passes, is in the form of a slit, to allow it to be adapted with ease to different sizes.

As the brass socket rises as well as the wood, (and this is indispensible to secure the parallel rising of the wood after each cut), it must be obvious that when, by being raised to allow taking off repeated cuttings, it has been brought almost to the knife, the apparatus must be readjusted, and the wood raised in the socket before more cuttings be taken off.

It need hardly be remarked that the cutting knife is ground to a perfect true and fine edge, without warp or bend, that it may move through a perfect plane. The accuracy and delicacy with which it works may be judged by .. a cutting made from so fragile a substance as a piece of charcoal”.

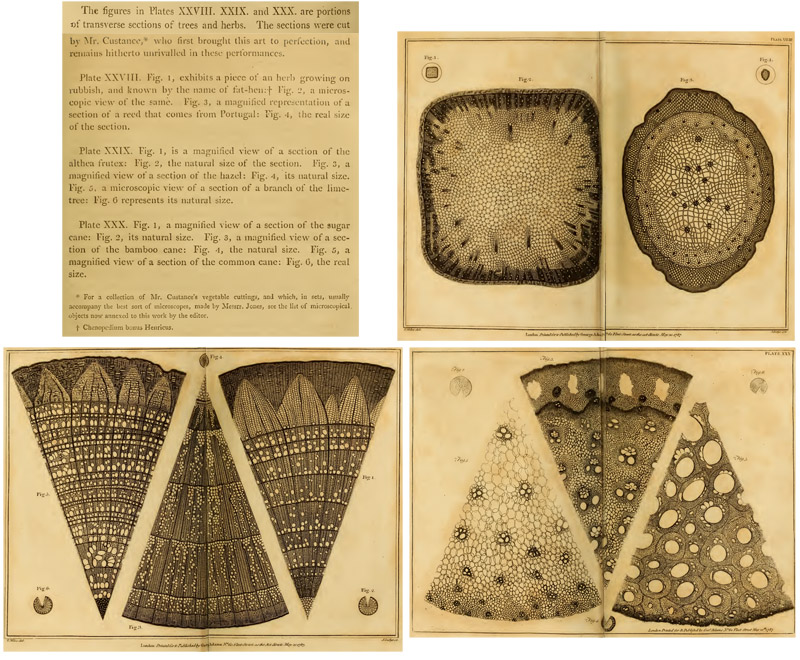

Figure 7.

Plates 28-30 of George Adams’ second edition,

showing microscopic views of botanical sections that were cut by Robert

Custance. The first edition showed the same figures, as plates 27-29.

Resources

Adams, George (1787) Essays on the Microscope, first edition, Adams, London, pages 21 and 679 and plates 27-29

Adams, George (1798) Essays on the Microscope, second edition, edited by Frederick Kanmacher, W. & S. Jones, London, pages 19-20, 598-599 and 709-710 and plates 28-30

Brewster, David (1832) The Edinburgh Encyclopedia, American edition, Parker, Philadelphia, page 253

Burial record of Robert Custance (1799) St. Marylebone parish records, accessed through ancestry.co.uk (note: it is from this record that we learn Custance’s first name. All other records refer to him as “Mr. Custance”)

The Critical Review (1798) Review of Adams’ second edition, Vol. 23, page 397

The Gentleman’s Magazine (1799) Obituary of Mr. Custance, Vol. 85, page 84

Gill’s Technological Repository (1829) Editor’s note, Vol. 5, page 197

Hill, John (1770) The Construction of Timber, from its Early Growth, Explained by the Microscope, Hill, London

Quekett, John (1855) A Practical Treatise on the Use of the Microscope, page 29

Smith, Gilbert M. (1915) The development of botanical microtechnique, Transactions of the American Microscopical Society, Vol. 34, pages 71-129

Smith, Thomas (1833) Mr. Custance, A Topographical and Historical Account of the Parish of St. Mary-le-bone, John Smith, London, page 311

Thornton, Robert John (1799) Account of the new machine invented by the late Mr. Custance, for making vegetable cuttings for the microscope, The Philosophical Magazine, Vol. 3, pages 302-305

Towers, John (1830) The Domestic Gardener’s Manual, Whittaker, Treacher and Co., London, page 279